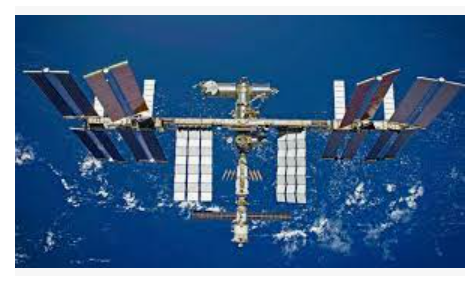

When you see the international space station floating in the upper atmosphere, it can look like a relatively fragile piece of machinery. This is partly true. It’s not the most robust of creations because, in many cases, it just doesn’t need to be. The upper atmosphere does not contain much chance of collision with a passing spaceship, and it’s too high for the satellites and assorted “space junk” orbiting around us. One thing about it that is worrying, especially for those astronauts on it, is that it is slowly decaying in its orbit. This means that if the Russians, NASA or the European Space Agency don’t send a rocket up to push it higher, it will fall to earth. So the developing Chinese space program may have to be called upon at some point if things continue.

Solar winds and radiation are constantly bombarding the astronauts. Without the Earth’s atmosphere to protect them, they run the risk of getting various cancers. In addition, getting a good workout at zero gravity is impossible, and muscle atrophy is also widespread. The casing of the station is toughened and designed to absorb most of these harmful elements, but it can never be as effective as the planet itself.

The life support systems that make up the station’s food, water, and oxygen providers also protect the astronauts. The other systems that allow the crew to do their experiments and monitor conditions on board and on earth also need to be protected. Making sure that these lifesaving diodes resistors and sensors are still in tip-top shape is a vital part of the operation.

For such components to work, they need to be created in perfect conditions and sealed afterwards. It’s why when making them, the best material to coat them in is Nickel. Nickel rarely rusts, doesn’t tarnish, doesn’t conduct heat so as to become too hot, and it’s excellent at resisting dust and debris, making it easy to clean. So it’s why Electroless Nickel Coating, like that from poeton.co.uk/standard-treatments/electroless-nickel-plating/, is the perfect place to ensure it is done correctly.

Once the nickel is in place, it affords a massive level of protection and performance from the components for years. This is also a great advantage as changing them can be costly and complex.